While OMM (Open Metal Mask) is a part used for vacuum deposition of the organic film, which plays a functional role on the OLED substrate, on the entire display, FMM (Fine Metal Mask) is a thin metal plate used for vacuum deposition of pixels that emit 3 lights of red, green, and blue in the OLED display manufacturing process. It is a metal mask that is used to accurately vacuum-deposit high-resolution color components.

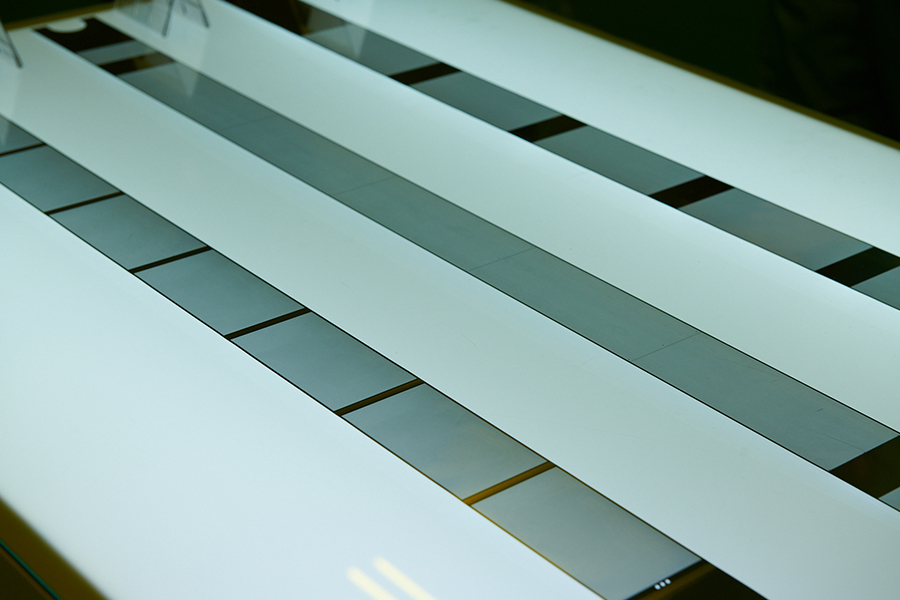

FMM has fine holes of 10 to 20 micrometers and it looks like a crater when enlarged.

The key of high-resolution OLED manufacturing is in the vacuum deposition process to create RGB pixels. Here, FMM plays a role of a key part that allows the vacuum-deposited organic materials to be precisely deposited only in the TFT pixel area.

Therefore, the uniform size of the fine holes of FMM, the cross-sectional angle and step height of the fine holes, and positional accuracy are the most important factors in the FMM manufacturing process. Also, any defects, such as deformation, stamping, blocking, sticking, foreign substance, etc. are not allowed in the FMM visual inspection.

Poongwon Precision is equipped with advanced research and manufacturing facilities and has secured many patents by constantly spurring R&D to produce perfect FMMs that meet global standards.

With the rapid increase of OLED demand in the smartphone market, display manufacturers are increasing OLED production and the demand for FMM is being increased together.

Since 2017, Poongwon Precision has participated in the mobile FMM market with high entry barriers, competing with leading companies in the global material field.